At Cascadia Seaweed, we cultivate local species of seaweed and manufacture products for crop and cattle farmers.

The cultivation team is leading an ongoing collaborative effort between Cascadia Seaweed and Hortimare, a company from the Netherlands that specializes in propagating seaweed.

The mission is to conduct direct seeding trials and to measure its effectiveness compared to our traditional method of cultivating seed on twine. These trials are taking place with Sugar kelp (Saccharina latissima) from the James Island farm in W̱SÁNEĆ Territory.

This season our cultivation team is preparing 120 km of seeded line (up from 90 km last year) for deployment over our 7 farm sites and the 10 km of test line deployed in Northern BC.

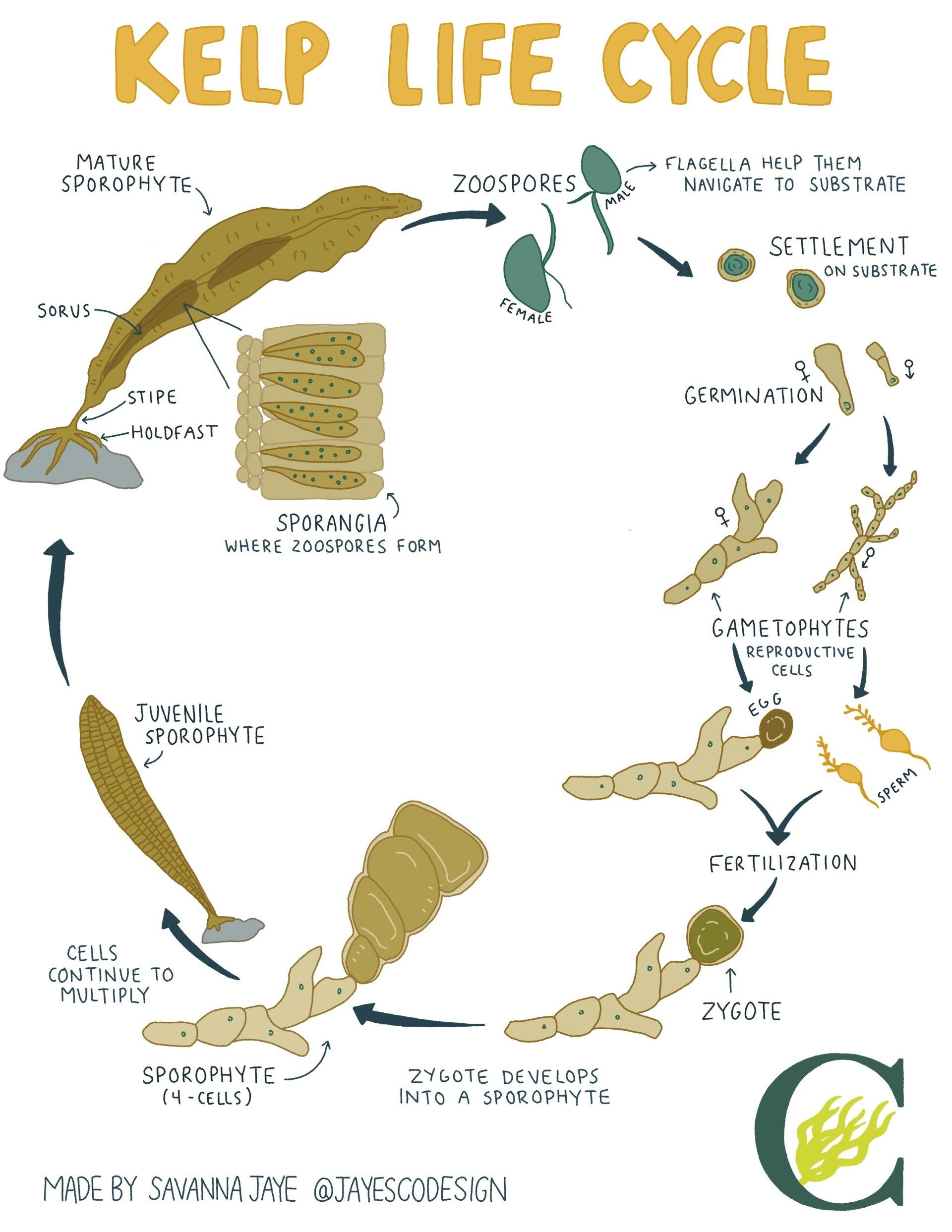

Traditional seeding: allowing zoospores to attach to twine in a nursery environment, then left to grow to the sporophyte stage in aquaria, which takes approximately 45 days. Our current nursery arrangement allows a maximum of 12 spools of 100 meters to be cultivated in each aquarium. Twine is then wrapped around our production line when outplanted.

Direct seeding: applying gametophytes or sporophytes directly to a specialized porous production line using an algae binder, an environmentally and biologically safe glue, with Hortimare’s proprietary direct seeding machine which applies a controlled quantity of solution and binder. This method requires less space and time than traditional seeding, and has significant potential to reduce waste and overall labour requirements.

Last fall, the cultivation team collected reproductive material of Saccharina latissima from our James Island farm, and then shipped the zoospores to Hortimare in the Netherlands where they were cleaned, separated into males and females, bulked (a process of producing additional gametophytes through fragmentation) and induced to produce sporophytes.

Those sporophytes returned to BC to undergo a small, yet successful, direct seeding trial on 100 meters of line at James Island last year.

Those same cultures were bulked again and returned last month for a larger trial. Using Hortimare’s proprietary direct seeding machine, which provides an even application of sporophyte solution, we successfully seeded 900 meters of production line and outplanted that line in 3 sections at the James Island farm.

The production line used for direct seeding is a 12 strand braided polyester that provides more surface area for juvenile sporophyte adhesion as opposed to the 3 strand that is used for the seeded twine method.

Dr. Jennifer Clark indicated that although direct seeding requires less space (a lab for incubators and clean cultures compared to a lab and a nursery housing many aquaria) and reduces time from 45 to 21 days, there is still a lot to learn about direct seeding in BC waters and biomass can sometimes be variable.

Over the next few months, our team will monitor the growth of both seeding methods with the intent to further evaluate the benefits and risks of shifting our production from solely traditional seeded twine to include direct seeding techniques. We will also continue our collaboration with Hortimare to further improve the equipment, seed quality, and scalability of this technology.

Direct seeding has been under development globally for a little over a decade, historically it has not produced consistent yields as the seeded twine method has, however, substantial improvements have been made at the research level to increase the consistency and repeatability of outcomes. For Cascadia, this is critical to further progress as this is one pathway to greatly increase our overall efficiency in seed development and deployment while reducing our waste and energy consumption.

"We value the work with the Cascadia team who are driven, ambitious and knowledgeable. We identify Cascadia as an important driver in the industry and their ultimate success will benefit all in the seaweed space."

Josh Masel, Technical Facility Manager at

Hortimare

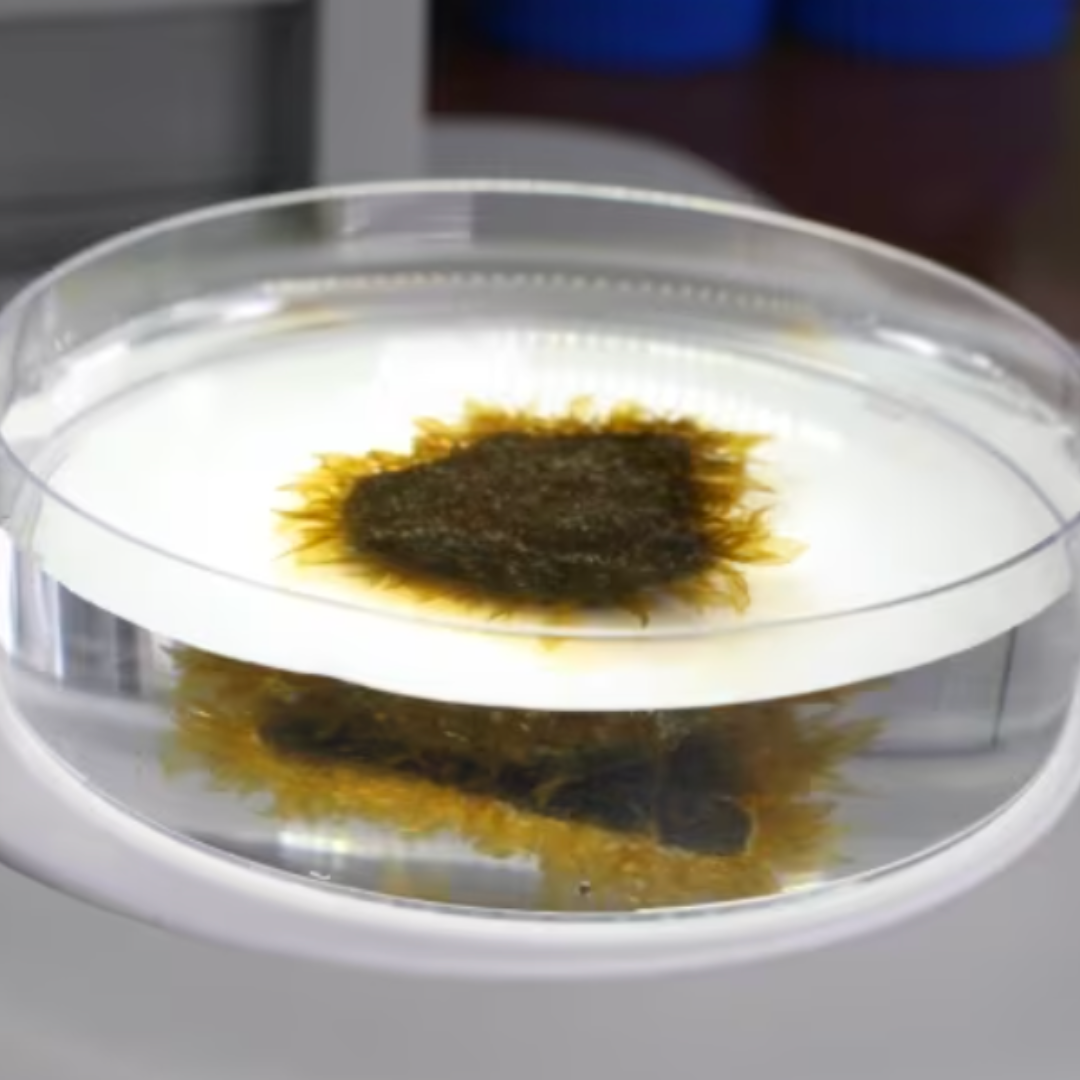

Direct seeding trial of Saccharina latissima at the James Island farm in May of 2021.

C - 9774 Third Street Sidney British Columbia V8L 3A4

Email: info@cascadiaseaweed.com

Phone: 1-778-351-4484

9774 - C Third Street Sidney British Columbia V8L 3A4

Email: info@cascadiaseaweed.com

Phone: 1-778-351-4484